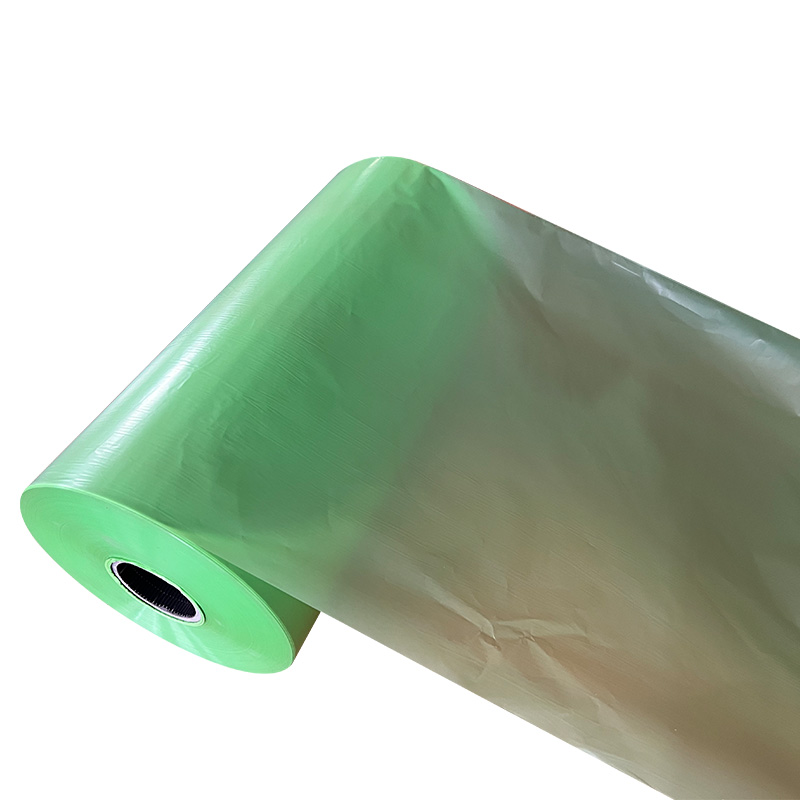

In the context of packaging emulsion explosives, the use of a strong cross film (also known as a cross-linked film or cross-laminated film) offers several advantages in handling and processing:

Strength and Durability: Cross films are typically made by laminating multiple layers of film together with a crisscross pattern. This results in a film that is exceptionally strong and tear-resistant. When handling emulsion explosives, which can be sensitive and hazardous materials, a strong film ensures that the packaging can withstand rigorous conditions without tearing or puncturing easily.

Barrier Properties: Emulsion explosives often require packaging that provides a barrier against moisture, gases, and contaminants. Cross films can be engineered with specific barrier properties to protect the contents from environmental factors that could potentially compromise their stability or safety.

Ease of Sealing: Cross films are compatible with various sealing methods, including heat sealing and adhesive sealing. This flexibility in sealing methods ensures that the packaging process is efficient and secure, minimizing the risk of leaks or contamination during transportation and storage.

Uniform Thickness: The manufacturing process of cross films ensures a uniform thickness throughout the material. This uniformity is crucial in packaging emulsion explosives because it provides consistent protection and structural integrity across the entire package.

Customization Options: Manufacturers can customize cross films to meet specific requirements such as size, thickness, barrier properties, and printability. This allows for tailored packaging solutions that optimize the handling and processing of emulsion explosives according to industry standards and safety regulations.

The strong cross film used in packaging emulsion explosives enhances safety, reliability, and efficiency in handling and processing these sensitive materials, ensuring they reach their destination securely and intact.

English

English 中文简体

中文简体